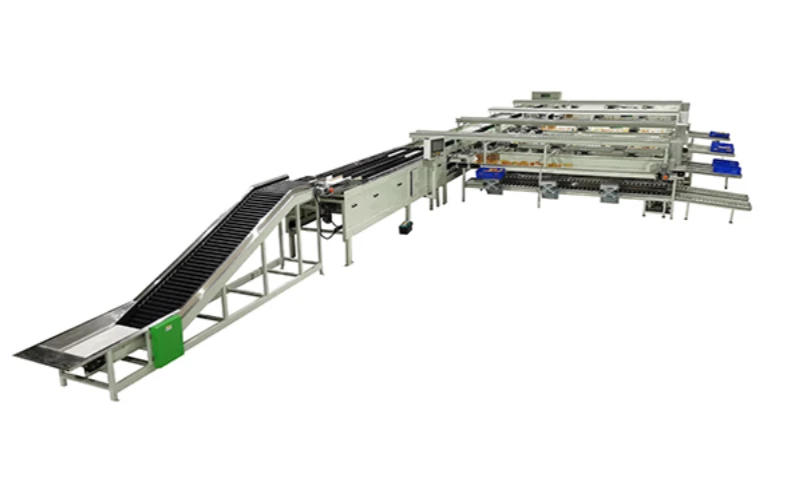

Tomato Sorting Packing Line

Not one-size-fits-all — we customize.

Model:JCFQ-40000D

Applications:Tomato, apple, orange, avocado, kiwi, etc.

Dimension:24200*8700*1680mm

Grade:8+1 grades

Capacity:6t/h

Voltage:380V

Power:8.47kw

This JC SORT tomato electronic weight grading production line consists of four parts: an elevator, a weight grader, an empty box conveyor, and a packaging table. The tomatoes are poured into the elevator, conveyed to the fruit arrangement channel, and then enter the weight grader to sort out the weight of each tomato. The empty turnover baskets are placed on the conveyor and transported to the back of the grader. They are manually placed on the unpowered roller on the packaging table and transported to the end of the packaging table. The graded tomatoes are transported to the packaging table via the conveyor belt. The tomatoes on the two grade conveyor belts are transported to the combined packaging table respectively. The conveyor belts of the packaging table for each grade of tomatoes can be circulated. The packaging worker takes the frame from the unpowered roller above and places the tomatoes on the split electronic scale. After the weight is reached, they are placed on the conveyor at the bottom layer and transported out.

Welcome to contact us to start a pleasant cooperation!

For further information about our products, please fill out the form below and one of our sales team will contact you as soon as possible.