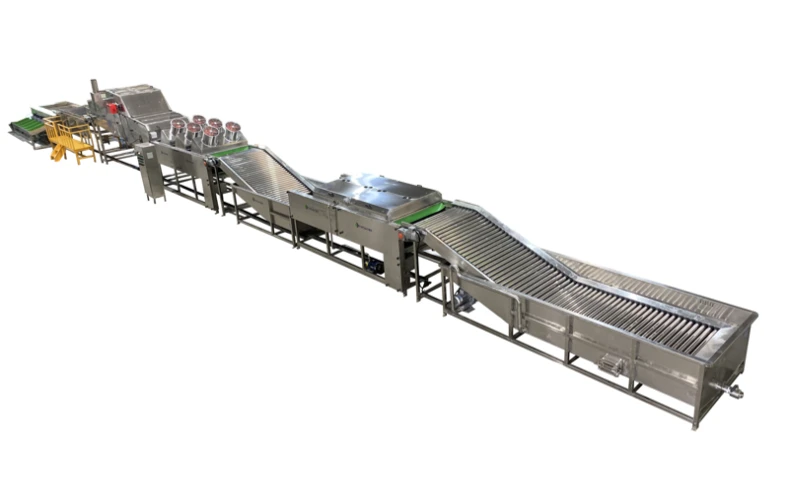

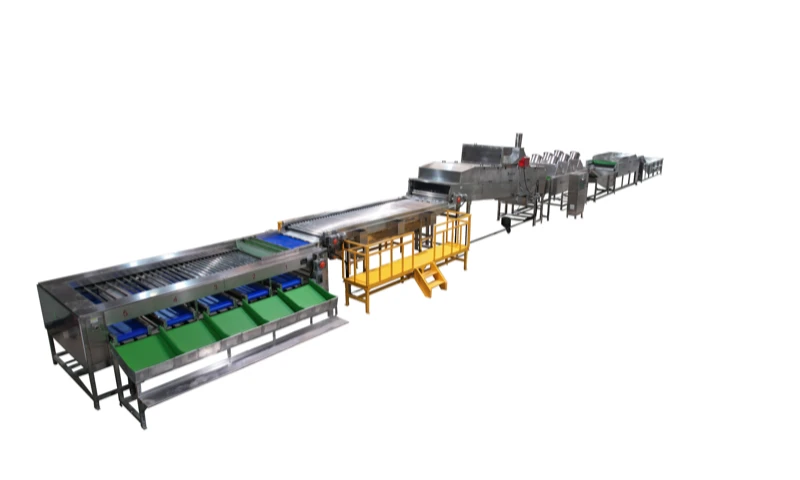

Sweet Potato Washing Drying Sorting Line

Not one-size-fits-all — we customize.

Model:JCHS-6000I

Applications:Sweet potato, potato, carrot, onions, bell pepper, etc.

Dimension:30200*3800*2780mm

Grade:5 grades

Capacity:6-8t/h

Voltage:380V

Power:19.33kw

This JC SORT sweet potato cleaning and grading machine is composed of 9 parts: bubble elevator, high-pressure brush cleaning machine, disinfection pool, polishing air-drying machine, dryer, fruit picking table, grading machine, simple packaging table and telescopic roller. Pour the sweet potatoes into the bubble elevator to soak the soil, then enter the high-pressure brush cleaning machine to clean, then enter the disinfection pool to soak, and then enter the polishing air-drying machine to brush the moisture on the surface of the sweet potatoes, and then use the dryer to dry. The moisture on the surface of the sweet potatoes can be completely dried without damaging the internal cells of the sweet potatoes. Then, the rotten fruits are manually selected on the fruit picking table to select out The rotten fruits can be directly thrown into the discharge hopper for transportation. The grader is a roller-type grader. The roller-type grader drives the rollers on the grading bed to move forward in parallel through the rotation of the pitch, and gradually increases the gap between the rollers to reach the corresponding size of the sweet potato, so that the sweet potato falls from the gap between the rollers to the fruit conveyor belt and is transported to the simple packaging table. The empty frames are transported by unpowered rollers above the packaging table, and sweet potatoes of different sizes are packaged directly by manual empty frames. The packaged sweet potatoes are directly transported by the powered rollers below for manual sealing.

Welcome to contact us to start a pleasant cooperation!

For further information about our products, please fill out the form below and one of our sales team will contact you as soon as possible.